Aluminum Bends for Precision Fabrication, Optimized Flow, and High-Performance Systems

Aluminum Bends as Essential Components in Advanced Fabrication and Performance Engineering

Aluminum Bends are a foundational element in modern fabrication, especially in applications where controlled airflow, structural efficiency, and weight reduction are critical. From automotive performance systems to industrial piping and custom fabrication projects, bent aluminum sections allow engineers to design complex routing without compromising strength or efficiency. Within the first stages of system planning, the choice of aluminum bends directly affects flow dynamics, space utilization, and long-term reliability. Their lightweight nature combined with excellent corrosion resistance makes them indispensable for projects that demand both performance and durability.

Understanding Aluminum Bends and Their Functional Role

Aluminum bends are pre-formed tubing sections designed to change direction smoothly within a system. Unlike sharp joints or segmented connections, properly engineered bends maintain a consistent internal diameter, reducing turbulence and pressure loss. This is especially important in applications such as intake systems, intercooler piping, and fluid transfer lines, where uninterrupted flow directly influences performance. Aluminum as a base material further enhances these advantages by offering predictable mechanical properties and excellent thermal behavior.

Precision Forming and Dimensional Accuracy

High-quality aluminum bends are manufactured using controlled forming processes that preserve wall thickness and structural integrity throughout the curve. This precision ensures uniform strength across the bend, preventing weak points that could fail under pressure or vibration. Dimensional accuracy also simplifies installation, as components align correctly without excessive adjustment. For fabricators, consistent bend geometry reduces fabrication time and improves overall system reliability.

Material Advantages of Aluminum in Bent Tubing

Aluminum’s natural properties make it particularly well-suited for bent components. Its low density significantly reduces system weight, which is critical in performance-driven environments. At the same time, aluminum alloys used in bends offer sufficient strength to handle mechanical stress, pressure, and vibration. The naturally forming oxide layer on aluminum surfaces provides inherent corrosion resistance, protecting the bends from moisture, road contaminants, and chemical exposure.

Corrosion Resistance and Environmental Durability

In both automotive and industrial settings, components are exposed to harsh conditions that can accelerate material degradation. Aluminum bends resist rust and corrosion without requiring heavy coatings, ensuring long-term durability. This resistance is especially valuable in applications exposed to heat, humidity, or chemicals, where steel alternatives may degrade more quickly. As a result, aluminum bends contribute to extended service life and reduced maintenance demands.

Flow Efficiency and Performance Optimization

One of the most critical benefits of aluminum bends lies in their impact on flow efficiency. Smooth-radius bends minimize airflow disruption, reducing pressure drop and turbulence. In performance automotive systems, this translates to improved throttle response, consistent boost pressure, and better overall efficiency. For fluid or air transfer systems, maintaining laminar flow reduces energy loss and enhances system stability.

Importance of Bend Radius Selection

The radius of an aluminum bend plays a significant role in performance outcomes. Larger-radius bends allow smoother transitions and better flow characteristics, while tighter bends save space but may increase turbulence if not properly engineered. Selecting the appropriate bend radius involves balancing spatial constraints with performance requirements. High-quality aluminum bends offer a range of radii to accommodate diverse design needs without sacrificing efficiency.

Fabrication Flexibility and Custom Applications

Aluminum bends are highly valued in custom fabrication because they simplify complex routing challenges. Instead of fabricating multiple straight sections and joints, builders can use pre-formed bends to achieve precise angles and smooth transitions. Aluminum’s excellent weldability allows these bends to integrate seamlessly into custom assemblies. This flexibility supports bespoke designs in automotive builds, industrial frameworks, and specialized equipment.

Fabricators sourcing premium Aluminum Bends benefit from consistent material quality and accurate forming. Reliable components reduce fabrication errors and ensure predictable performance in finished systems.

Automotive Applications and System Integration

In automotive engineering, aluminum bends are commonly used in intake systems, intercooler piping, cooling lines, and exhaust-adjacent components. Their lightweight construction contributes to improved vehicle dynamics, while smooth internal surfaces support efficient airflow. For turbocharged engines, maintaining consistent pressure and minimizing lag is essential, and well-designed aluminum bends play a crucial role in achieving these goals.

Vibration Resistance and Structural Stability

Vehicles generate constant vibration that can fatigue poorly designed components. Aluminum bends maintain structural stability under vibration due to uniform wall thickness and proper alloy selection. When installed correctly, they resist cracking and deformation, ensuring long-term reliability. This stability is critical in high-performance or off-road applications where components are subjected to continuous stress.

Thermal Performance and Heat Management

Aluminum’s excellent thermal conductivity allows bends to dissipate heat efficiently. In systems exposed to elevated temperatures, this property helps regulate thermal load and protect adjacent components. Aluminum bends cool quickly after heat exposure, reducing the risk of heat soak and maintaining system efficiency. This makes them suitable for applications near engines, turbochargers, or other heat-generating equipment.

Consistency Under Thermal Cycling

Repeated heating and cooling can cause materials to expand and contract, leading to fatigue over time. Aluminum bends handle thermal cycling predictably, maintaining their shape and strength. This consistency ensures that joints remain sealed and aligned, preventing leaks or performance loss. For long-term applications, predictable thermal behavior is a key advantage.

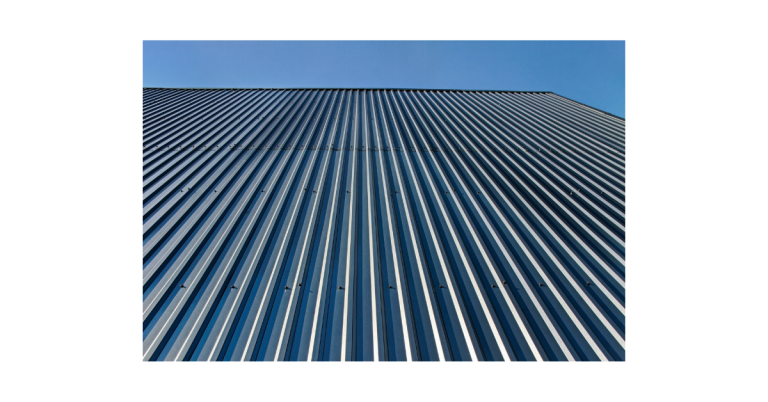

Aesthetic Value in Visible Installations

Beyond functional benefits, aluminum bends contribute to a clean and professional appearance. Their smooth curves and uniform finish enhance visual appeal in exposed systems such as engine bays or industrial displays. Polished or anodized aluminum bends add a refined aesthetic while retaining all functional advantages. For builders who value presentation alongside performance, aluminum bends offer an ideal balance.

Finishing and Customization Options

Aluminum bends can be polished, powder-coated, or anodized to meet specific design or protection requirements. These finishing options allow customization without compromising material properties. Enhanced finishes can improve corrosion resistance further or align with branding and design themes, increasing versatility across applications.

Cost Efficiency and Long-Term Value

While aluminum bends may represent a higher initial investment compared to basic steel alternatives, their long-term value is substantial. Reduced weight improves efficiency, corrosion resistance lowers maintenance costs, and durability minimizes replacement frequency. Over time, these factors result in lower total ownership costs and more reliable system performance.

Builders and engineers often return to trusted suppliers offering high-quality Aluminum Bends to ensure consistency across projects. Dependable sourcing supports repeatable results and professional-grade outcomes.

Future Trends and Expanding Use Cases

As engineering standards evolve, the demand for lightweight, efficient materials continues to grow. Aluminum bends align perfectly with these trends, supporting innovation across automotive, industrial, and manufacturing sectors. Advances in forming technology and alloy development continue to improve strength, precision, and application range. This ongoing evolution ensures that aluminum bends remain a critical component in future-focused designs.

Aluminum bends embody the intersection of performance, efficiency, and adaptability. Their ability to support complex routing, maintain flow efficiency, and withstand demanding environments makes them indispensable in modern fabrication. By combining lightweight construction, corrosion resistance, and precise engineering, aluminum bends continue to set the standard for high-performance and custom-built systems.