Plastic Machinery: A Strategic Guide for Modern Manufacturing

The global manufacturing sector relies heavily on plastic machinery to meet growing demand for durable, lightweight, and cost-effective products. From packaging and automotive parts to consumer goods and medical devices, every industry depends on machines that mold, shape, and produce plastics efficiently. In 2025, businesses are not only seeking robust production capacity but also energy efficiency, automation readiness, and reliable after-sales support. This guide explores the fundamentals of plastic machinery, its categories, applications, and why working with an industry leader such as Daoben Machinery provides a long-term advantage.

What is Plastic Machinery?

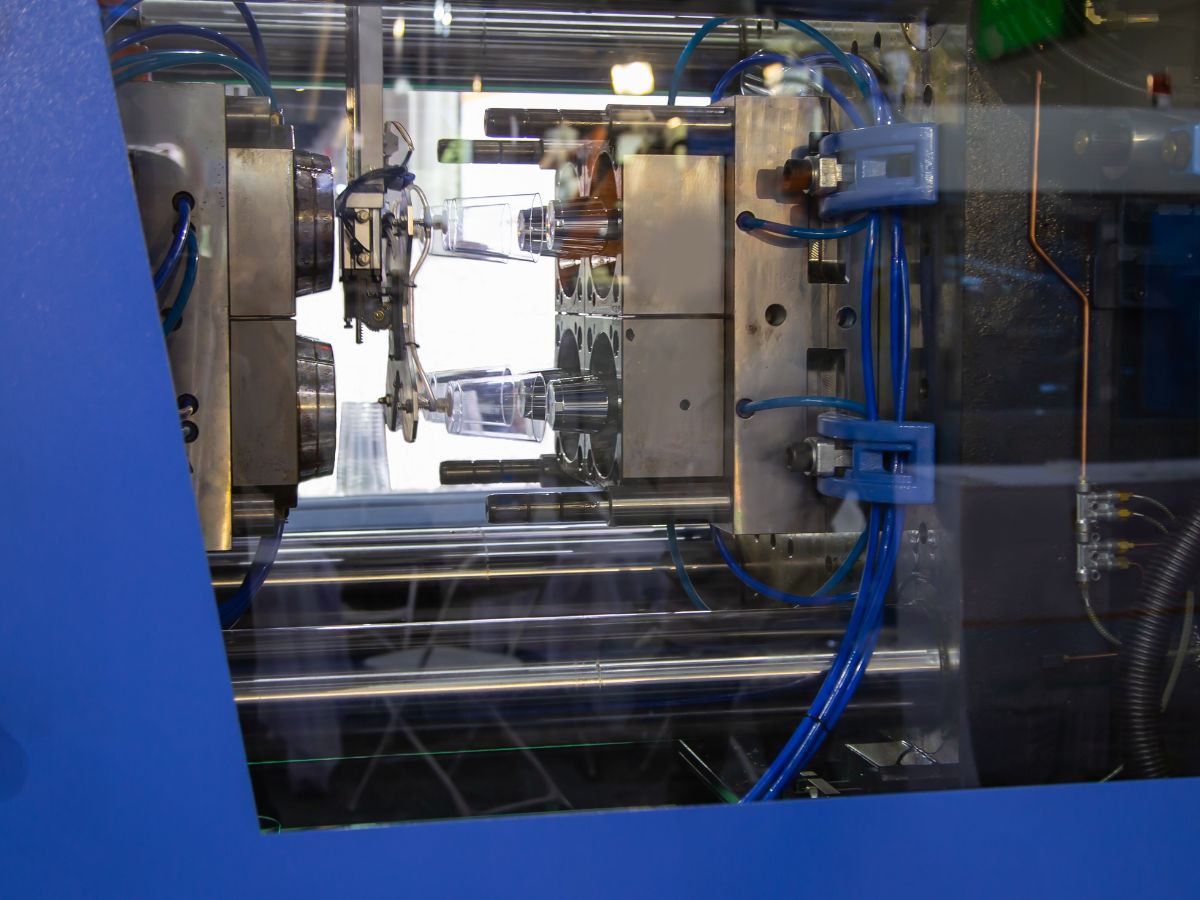

Broadly, plastic machinery includes all equipment used to process raw polymers into usable products. This spans from extrusion and blow molding units to injection systems. However, the most common and versatile equipment remains the plastic molding machine, also known as an injection molding machine or moulding machine.

The role of plastic machinery is simple yet powerful: convert raw pellets or granules into high-quality, repeatable parts at scale.

Major Categories of Plastic Machinery

| Machine Type | Function | Best Applications |

|---|---|---|

| Injection Molding Machine | Injects molten resin into molds | Automotive parts, medical devices, consumer goods |

| Blow Molding Machine | Produces hollow products | Bottles, containers, tanks |

| Extrusion Machine | Pushes molten polymer through a die | Pipes, profiles, sheets, films |

| Thermoforming Machine | Heats sheets and forms them into molds | Packaging trays, food containers |

Among these, the plastic injection molding machine is considered the backbone of many industries due to its precision and versatility.

How Plastic Machinery Powers Key Industries

- Automotive: Lightweight dashboards, bumpers, trims, and under-the-hood components.

- Medical: High-precision syringes, vials, surgical tools, and diagnostic devices.

- Consumer Goods: Household appliances, toys, storage containers.

- Electronics: Connectors, casings, and intricate housings.

- Packaging: Bottles, caps, films, trays, and custom containers.

This breadth of applications demonstrates the flexibility of plastic machinery in adapting to market needs.

Key Features Buyers Should Evaluate

When selecting plastic machinery, buyers must consider:

- Capacity and Tonnage – Determines the size of products and molds the machine can handle.

- Drive System – Hydraulic, servo-hydraulic, or all-electric systems influence efficiency and precision.

- Control System – Advanced HMIs allow precise process monitoring and automation integration.

- Cooling and Temperature Control – Directly affects cycle time and product quality.

- Compatibility with Auxiliaries – Ability to integrate with dryers, robots, and QC systems.

- Maintenance and Longevity – Machines with easy-to-service parts and global support ensure less downtime.

Plastic Machinery in 2025: Trends to Watch

- Energy Efficiency: Rising energy costs make servo and electric machines highly attractive.

- Automation: Robots, vision inspection, and IoT integration for smart production cells.

- Material Innovation: Adaptability for recycled plastics and biodegradable polymers.

- Customization: Industry-specific solutions for automotive, packaging, and healthcare.

- Sustainability: Machines optimized for lower waste and circular economy practices.

These trends shape investment decisions as factories modernize.

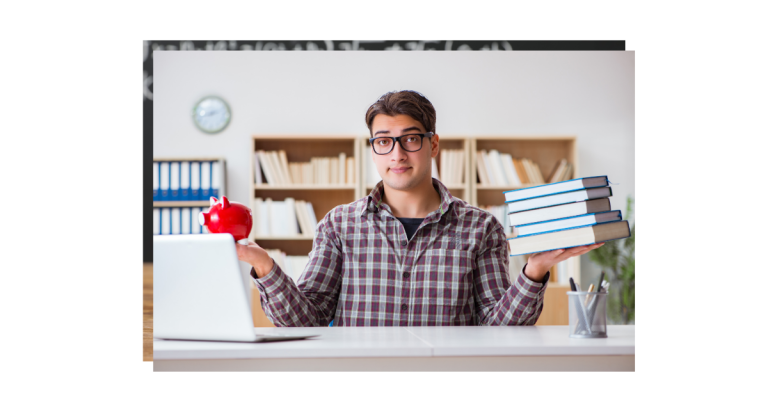

Cost Considerations

Plastic machinery pricing is influenced by:

- Machine type and tonnage capacity.

- Drive system selection (hydraulic vs. electric).

- Automation features.

- Warranty, service, and spare parts support.

Investors often balance upfront costs with lifecycle expenses, where energy savings and reduced downtime deliver strong ROI.

Maintenance Best Practices

To extend equipment lifespan:

- Daily: Inspect heaters, screws, and resin feed system.

- Weekly: Clean filters and check pressure stability.

- Monthly: Evaluate hydraulic oil condition and platen alignment.

- Yearly: Conduct full calibration, safety tests, and replace wear components.

Preventive care lowers scrap rates and ensures stable production cycles.

Why Choose Daoben Machinery

Daoben Machinery stands out in the global market for delivering high-performance plastic machinery solutions. Their strengths include:

- Wide Product Range: Covering injection molding machines of multiple tonnage sizes.

- Energy Efficiency: Servo-driven systems cut operating costs.

- Integration Ready: Designed for seamless automation with robots and vision systems.

- Global Support: Spare parts supply and strong after-sales service worldwide.

- Customization: Tailored configurations to match industry-specific needs.

Businesses that partner with Daoben Machinery gain more than equipment—they gain a dependable manufacturing solution.

Final Thoughts

In today’s competitive landscape, investing in the right plastic machinery is a strategic decision. The correct machine delivers precision, reduces cycle time, minimizes waste, and lowers overall production costs.

For businesses planning growth in 2025, exploring solutions with Daoben Machinery is a practical step. A trusted molding machine manufacturer not only provides advanced equipment but also long-term reliability, ensuring your production lines remain competitive well into the future.